- Precision and accuracy: Unlike the traditional approaches of cutting materials, plasma cutting tends to offer greater precision and accuracy when it comes to cutting based on specific measurements. Designed with special gears, these cutters operate on computerized software.

- Greater efficiency: The great ease of cutting that these cutters offer to you makes the process much more efficient. Minimal training is needed so your operator can manage any kind of complicated adjustments comfortably.

- Diverse application: You can ideally use these machines for cutting a variety of materials whether ferrous or non-ferrous. In fact, you can also easily cut metals with more than a 3-inch gauge thickness.

Thursday, December 22, 2016

Advantages of Plasma Cutting Machines – An Alternative for Oxy-Fuel with Multifarious Benefits

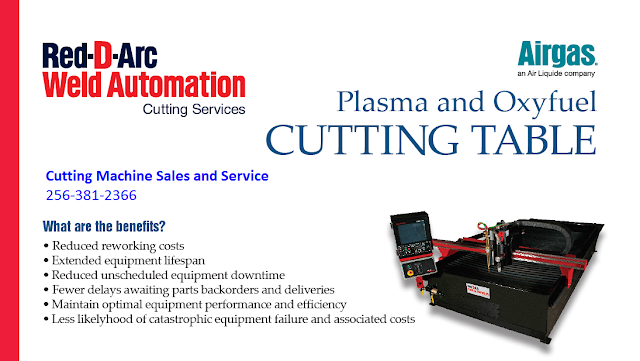

Although, various traditional methods like oxy-fuel cutting machines are also available in the market, the plasma cutters have a cutting edge over others.

Plasma Cutting vs. Oxy-Fuel

An oxy-fuel cutting machine is another important tool for cutting materials like steel and aluminum. With such diverse options available in the market, you may find great difficulty in choosing the best. Of course, the selection becomes quite obvious when you compare the traditional tools with plasma cutting machines.

Although, they both have their own advantages and disadvantages, the plasma cutters find their extensive usage in cutting of non-ferrous materials like stainless steel, aluminum as well as cast iron. Furthermore, when it comes to precision and speed, the plasma cutters offer many advantages over the oxy-fuel cutters.

CNC Plasma Cutting Advantages

Occupying a significant role in the manufacturing and construction industries, a CNC plasma cutting machine offers multiple benefits for the users including:

Friday, November 25, 2016

Top 5 Things to Consider When Purchasing or Renting a Welder

There are numerous procedures to join metals using the

welding process. All these procedures convert power to heat in the welding

region that leads to softening, synthesis, and linking. Notably, a welder is an eminently hand gripped

piece of equipment. Several others are computer guided that are effective in

processing several welds at one time or distinct welds in a short amount of the

time. Welders find their use in many structures and range from small workshops

to large specialized industries and more.

Types of Welders

- MIG welders

- TIG welder

- Spot welders

- Molded welders

Key

industries consider welders a long-term investment, which makes it important

for the buyer to consider many things before making a purchase. The conditions

will depict the requirement for the appropriate type of welding procedures and

the best equipment to suit their needs.

Things to consider before buying a welder:

- It is important to understand the different types of plasma cutting and the processes used to link two materials by softening and joining them.

- It is critical to know what type of material is going through the welding process. In spite of being the easiest method, it helps in joining the most common metals like aluminum, stainless steel, and carbon steel.

- It is important to recognize the time factor requirements, which can affect the welding process. This is crucial because the processing of different equipment accompany different duty cycles.

- A basic factor to consider during the welder research stage is the availability of the power and the flexibility.

Think twice before choosing

Selecting

an appropriate welder supplier is a

very crucial decision, especially when the industry relies on equipment

processing. Opting for a perfect supplier for the welder can enable the

industry owners to enjoy maximum benefits. Industries that shut down after a

short period due to wrong selection of machine suppliers need to learn a lot

from such key players in the welding machine industry.

Thursday, November 24, 2016

Stick Welding Machines: Things to Consider For Lease or Sale

Stick welding, also known as shielded metal arch welding, is a common process for joining various machine parts. Depending on the application, stick welding machines undergo lots of alterations in terms of size, shape, costs, and more.

Want to own one?

If you are considering purchasing or leasing this equipment, it is important to address your requirements first. Here are few important points to consider:

- Metal type: Make sure that you know about the type of metal that requires the welding, whether steel, stainless steel, cast iron, etc.

- Thickness: Be aware of the thickness of the fixture or base metal you’re working. Notably, stick welder machines are good for structural pipe and steel with around half inch thickness

- Welding location: Decide the place to do your welding in advance, for example a warehouse, shop or an open area, the requirement for the machine type will vary accordingly.

- Product comparison: Go through the specifications of the shortlisted machines and compare them for duty cycle, open-circuit voltage, thermal overload protection, etc. Choose the best one to suit your needs.

- Other aspects: Be aware about the concerns related to buying/leasing, transporting and storing of the stick welding machines in advance.

Here is a quick look at the varied features of this widely used equipment:

· Energy resource – It includes:

Ø Alternate current converter

Ø Direct current fixer

Ø DC alternator

Ø AC/DC converter fixer

· Ionholder&cords

· Defensive segments– includes:

Ø fist covering & welding helmet

Ø body cover or the apron

Importance of location

If the welding process is occurring in a welding shop, then there should be availability of the effective ventilation structure, which eliminates the harmful welding gases. The welder may also face distinct obstacles such as dangerous impacts of ultra-violate radiations and hot gases emitted by the arc welding process.

Widespread availability

Companies offering these services lease their equipment throughout the world. Their employers and the unique equipment all serve to meet the specific needs of the clients. The functions and the authenticity of their machines in even the most extreme situations are remarkable and worth utilizing.

Friday, October 7, 2016

The Thriving Market of Different Types of Power-Generation Equipment Rentals and Services

The demand for power generation equipment

on rent has witnessed an appreciable surge in the recent past. Especially,

people residing in geographical locations in the Middle East, Asia Pacific and

Africa have been among the major consumers of these equipment. This is because

of myriad power related problems in these regions, such as load shedding, grid

instability, unavailability of power for a short or long term, and so on.

Several other important factors such as seasonal demands,

construction activities, occasional requirements, etc also contribute

appreciably to the power rental market. If you are residing in any of these

locations or run the requirement for construction or other purpose, it is

important to know the type of power generation equipment that could suit your

motive in the best way. Here is a quick summary of the types of power generation

equipment available.

Types of Rental

Power Generators

Diesel Generators: Depending on your suitability, you may rent or hire these

power generators from various brands. Different units are available with

distinct features such as quietech sound reduction, lockable storage box, delta

demand excitation, sophisticated sound absorbing technology, prime output

ranging between 25 kVA to 400kVA and more.

Diesel/NG

Generators: As you may

infer, these generators use either diesel or its combination with natural gas

to generate power. This makes way for lower operational costs and appreciably

savings on fuel consumption as compared to the diesel generators. You can

choose Hybrid Diesel / Natural Gas Generator with prime output ranging from

63kVA to 150 kVA depending on the model.

On a full load prior to refueling, these generators can run up to around

50 hours.

NG/LPG

Generators: Equipped to run

on LPG or Natural Gas fuels, these are more reliable, flexible and

environmentally safepower sources. The generator uses PSI-HD and a radiator

cooled gaseous engine that adheres to the existing Environmental Protection

Agency (EPA) regulations. Depending on the model, it generates prime output of

164kVA and 227 kVA.

Besides, you can also rent Paralleling Systems or Power Distribution Panels of renowned brands from reputed service

providers. While the former is best synchronizing multiple generators, the

latter is ripe for managing the electrical requirements of any jobsite.

A profitable business

prospect

All these

power-generation equipment rentals and the companies offering these rental

services altogether account for a thriving market. As per a recent report the

power rental market is expected to thrive at a CAGR of 12.9%, i.e., from $11.6

billion in 2015 to $21.3billlion by 2020, which is phenomenal.

Thursday, September 22, 2016

Stud welders and Welding Machines – Highly Demanded by Many Industries

Welding

is an important part of the industrial processes in which professional welders

join different parts to form functional machines with the help of a welding

arc. Stud welding is one widely used method that involves joining a fastener or

weld stud to another metal part, mostly a substrate or a base metal. The fastener

is mostly tapped, threaded, or unthreaded.

Knowing the machines

Stud

Welders use specific welding machines to perform the tasks. This equipment

operates on a direct current power supply and include a weld gun, cables and a

controller as its main components. Usually the controller and the power supply

combine to work as a single component called a “welder”.

How to Weld

The welding process is simple, if carried out by experts. Beginners need to undergo proper training before moving ahead with using the stud welding machine.

The welding process is simple, if carried out by experts. Beginners need to undergo proper training before moving ahead with using the stud welding machine.

- Load: Use a stud gun to place the welding stud in the base metal.

- Draw weld arc: Create a weld arc that melts the base of welding stud and a selected portion of the metal work piece to carry on with metal fastening.

- Insert welding stud: Force the welding stud into the melted portion and keep it in place until the solidifying of the metal takes place.

Two methods

You can do stud welding in milliseconds with the help of any of these two techniques:

- Arc Stud Welding

- Capacitor Discharge (CD) Stud Welding.

The

choice of either methods depends mainly on the kind of stud fastener required.

Then depending on the application you will weld the fastener together with the

base metal.

Multifarious Applications

Stud

welders and welding machines find a heavy use in a variety of industries

because of their usefulness in joining the metal parts with the specially

formed nut called as fastener. The variety of industries thus includes

aerospace, transportation, automotive, petrochemical, light & heavy-duty

equipment, shipbuilding, utilities, metalworking and many more.

Availability

While

you can buy these welding machines, renting them is still a better option because

of the exceptional savings you can make.

Reputed companies offer a wide range of user friendly and fully

regulated stud welders at affordable rates. You can have them in single or dual

gun versions as well as with varying duty cycles from any service centers near

you.

Saturday, August 27, 2016

Accurate & Versatile Bevelers for the Pipe Welding Industry

Pipe beveling, also known as pipe cutting and pipe profiling, refers to the mechanical industrial process designed for the specific profile of the pipe. This process forms a 37.5 degree angle for welding between the edge of the end of the pipe and a plane perpendicular to the surface. The use of the bevel is to soften the edge of the pipe piece in order to maintain security and wear resistance to facilitate joining with another piece.

The profile of pipe cutting is organized to maximize the fitting between two parts of the pipe. The complex cut includes straight cuts, miters, saddles and mid-section holes. The final goal of the cut is to prepare the pipe to join permanently with the help of arc welding.

The Function of Pipe Beveling Machines

The pipe beveling machines perform the cut by using a plasma or oxy-fuel thermal torch. This generates a direct flow of plasma in the jet, which further helps in the process of cutting, spraying or arc waste disposal. Pure oxygen is better than ordinary air because it can reach a much higher temperature. Acetylene is the most commonly used fuel in this process. Although is accompanies certain handling problems, it has the advantage over other fuels due to its high heat output.

The profile of pipe cutting is organized to maximize the fitting between two parts of the pipe. The complex cut includes straight cuts, miters, saddles and mid-section holes. The final goal of the cut is to prepare the pipe to join permanently with the help of arc welding.

The Function of Pipe Beveling Machines

The pipe beveling machines perform the cut by using a plasma or oxy-fuel thermal torch. This generates a direct flow of plasma in the jet, which further helps in the process of cutting, spraying or arc waste disposal. Pure oxygen is better than ordinary air because it can reach a much higher temperature. Acetylene is the most commonly used fuel in this process. Although is accompanies certain handling problems, it has the advantage over other fuels due to its high heat output.

The basic procedure of pipe beveling includes:

- Joint Preparation

- Root Weld

- Fill and Cap

- Testing

Pipe Beveler Tools

The tools used in the process of pipe beveling are as follows:

- Pipe Alignment & Reforming Clamps

- Pipe decent & Flange apparatus

- Hoist, Lifts + Cranes

- Generators & illumination

High tech pipe beveling tools are simpler to use compared to grinding tools. These tools help reduce the work load and aggravation associated with the process. Certified pipe tools can enhance productivity on the job site while providing accurate and efficient output.

The pneumatic high powered saws come in handy in various situations, such as in removing boiler panels. With the selection of the appropriate tool the individual work safely. The bolt tools can also convene the requirement of various applications and hold a widespread application in multiple industries.

Reason for automated pipe beveling

- Low operating cost, uses mostly industry standard carbide tooling.

- Eliminates ergonomic issues from operator handling hand tools.

- No more dirty operations such as hand grinding or torching.

Friday, July 22, 2016

Power Generator Rental: The Power Source for Many Businesses

A diesel engine driven welder or generator with multi-process capabilities offers great versatility. It helps accomplish what one needs for preparation in the current work force while providing the capability to do more in the future by boosting efficiency and saving fuel.

Completing jobs on time within a specific budget is very important to most companies and contractors. This can be difficult with the consistently raising cost of fuel, equipment and new government policies.

Power Generation Capabilities

With portable multi-process welders and generators, multiple workers can use the machine simultaneously for welding, powering lights, cutting and grinding. This also creates more space on a busy job site. Generators with multi-operator capabilities reduce the need for additional capital equipment purchases. This is because the generators have the potential to meet the needs for various different jobs. Generators provide other benefits such as:

- Reducing the need of additional equipment purchases

- Less fuel usage

- Less maintenance

A diesel engine driven welder or generator not only provides enough power for welding arcs but also provides sufficient power for inverter-based welding power sources. Auxiliary power and weld control are completely independent from the arc. However, the operators can weld many objects using auxiliary power without any impact on the arc quality.

Power Generation Benefits:

Since generators meet the needs of companies and industries and increases the amount of welding arc compared to traditional units, it encourages more power generation rentals. The simultaneous operation of the machine increases the workers comfort, safety and productivity. Some other benefits include:

- Portable

- Flexible usage

- Compact- saves space

- Reduces amount of equipment with its versatility

- Easy maintenance

- Increases productivity

- Reduces planning and costs

- Efficient and safe

Monday, June 27, 2016

Various Types of Welding Machines for Fabrication Process

Welding refers to joining of

metals and thermoplastics. Welding Machines can be widely arranged in

categories depending on process and equipment used during the process. They are

useful for some determination to achieve or manufacture something and the

welder needs a proper welding tool to obtain a good control over the work. It

comes in all shapes and sizes from home workshop welder to industrial welding

machine for car manufacture and specialized industries.

Wednesday, June 22, 2016

Different types of Arc Welding Machines gives you Speed, Quality and Productivity

Welding is one of various processes of joining metals. It is useful for creating an arc between electrode and base material to melt the metal at welding point. The entire process remains transparent for the steel fabrication of structures and vehicles. Arc Welding Machines has become very important and helpful in shipbuilding during the Second World War.

The Power Supply and electrical energy plays a crucial role in welding process. Voltage is the main factor while work is going on.It is very difficult to hold the electrode in a perfect and steady way. If the voltage fluctuates,in that case there is a need of constant power supply. Therefore, the regular supply of current should control the entire process.

Types of Machines

- Flux Cored Arc Welding (FCAW)

- Gas Metal Arc Welding (GMAW)

- Gas Tungten Arc Welding (GTAW)

- Plasma Arc Welding (PAW)

- Shielded Metal Arc Welding (SMAW)

- Submerged Arc Welding (SAW)

Benefits

- Arc Welding Machines are very versatile. It applies in variety of application and finds its use with a wide range of electrodes.

- This is very simple to use and easily portable instrument. It is very much cost effective.

- All the products are very compatible with carbon, alloy steels and low alloy and are ripe for welding thick materials.

- Products have very high deposition rates and the product is very reliable for out of position welding.

- Welding process is very convenient in remote and outskirts locations.

- Machine produces less radiation and very low amount of welding fumes.

- Machine produce welds with high quality and appearance.

- This is also specializes in thin welding sections and delicate works.

- It uses the soft switching inverter based technology, which is widely popular these days.

Thus, Arc Welding Machines has become very common now days. All machines come out in market with new technologies according to the trend and market demand. Today growth has increased a lot for joining numerous clients in the field of Aerospace equipments also. The demand of these durable is across the world. Various methods and technology offer one stop solution to observe the maturity of the product in the market. Effects of these products are very impressive in the entire industry.

Hence, the misconception regarding use of welding machines should be very clear to every user in the business. These machines are a boon in present generation.

Thursday, June 16, 2016

What Are the Benefits of A Stick Welding Machine?

Fusion of welding machines is on hype these days. The product is widely used in industries like construction, agriculture, transportation, mining and others. Effective in making high rise residence, pouring concrete on constructed area and building facades, Stick welding also plays an important role in building the insulation system. It is one of the top welding processes with religious applications in maintenance and repair industry.

Monday, May 30, 2016

RDA60T3S (Tier 3) Diesel Generator from Red D Arc

Red D Arc is one stop destination that offers portable welder generator, power driven diesel

welder generator and other

accessories for sale, lease and rent. Its sound-attenuated ultra-quiet mobile generators

blend design ease with uncompromising standards of engineering excellence. The

pioneering technology brings dual single and three phase power. Browsing

through its official website could enable you get more details about its high-quality

heavy duty products.

Important features of

Red D Arc’s diesel welder generator

Here is a look on some of the important features of this

generator:

- 60 kVA prime output

- Use of mega quiet innovative sound-absorbing

- Simul-phase technique brings dual single and three phase power at the same time

- Fuel-efficient, rugged diesel engine

- Exceptionally compact and light weight to fit into rigid spaces

- Generators can easily connect, are easy-to-operate and function a long duration amid fill-ups

- Single-phase 120V output accessible in all voltage settings

- High coolant temperature and low oil pressure result in automated shut-downs

- For trouble-free connection with auxiliary tanks, two-way tank valve is available

- The outer enclosure with the perfect blend of stainless steel fasteners and powder coat paint makes this portable welder generator, all-weather durable.

Friday, May 27, 2016

Why Second Hand Welders Should Be Your First Choice For Practicing Welding?

With the continuously evolving industrial

demands, the use of upscale welding technique is becoming quite popular in

assorted sectors. Owing to the inevitability of welding processes, the

organizations prefer hiring welders having deep knowledge of the process of

operation, competency to examine welding symbols from blueprints and better

working skills. Besides the individual expertise of the involved professionals,

the use of apt welding machine holds equal importance.

A welding machine is useful in

joining of metals by coalescence. It involves applying extreme heat to melt a

part of the metals to fix thus they intermix. Several kinds of used welding

equipment are easily accessible at cost effective prices from used industrial

machinery auctions.

Welding equipment at second hand market

In case, your business entails

spot welding equipment or arc welding, you can explore complete range of used

welding equipment to meet all your

requirements. However, it is quite usual that you may new get hold of a new welding

equipment instantly. At the most, the manufacturer could put you on the

wait-list that can take several months till you take delivery of your welding

tools and equipment. In such circumstances, opting for second hand welders is

perhaps a better and a recommended choice.

You can locate such equipment for

purchase within a reasonable distance from your industry, thus cutting down the

shipping charges. Buying used machines at the second hand market can spare around

50% off the cost of buying new. Thus, if you are longing for such machines,

evaluate the auction first, apart from squandering time anywhere else. When availing

these second hand welders on rent, make sure that it is perfectly usable and in

good condition.

Explore the used marketplaces and suppliers

You may find out several leading

suppliers and used marketplaces online offering the best quality, durable as

well as affordable welders. Depending on your choice of preference, you can explore

the best selection of second hand welding tools from these suppliers, like

portable welding machines, TIG welding machines, MIG welding machines and many

more. To check for the whereabouts of the used machine you are about to purchase,

make sure it is duly trialed and tested for proper functionality. Asking for

machine details page from the supplier can help you appreciably in this regard.

To conclude, welding machine manufacturers produce

distinct welding types to last longer that makes them reliable and durable.

However, if your prefer saving business expenditures and prompt delivery,

buying second hand equipment is always a better option.

Monday, March 28, 2016

Welding Equipment Suppliers: The Latest Metal Joining With Machines

Welding is a process of heating up various metals to a

saturation point in order to rejoin them. Welding is an industry to which many

of us are not familiar but it is a very important part of our economy. The need

for well qualified welders,to provide the high quality welding, is always in

demand.

Monday, March 21, 2016

Best Pipe Beveling Welding Equipment - To Do Your Work with More Comfort

Pipe beveling machines have comprehensive designs that offer easy setup and operation for the welding and beveling of pipes. Further, the precise fabrication of beveling machines takes place using superior quality raw materials into the equipment under the supervision of skilled professionals.

Thursday, February 25, 2016

Getsustainable Cleaning with Media Blasting Equipment

By Chris Brown2:20 AMinduction heating equipment, media blasting, proheat 35 air-cooled system, proheat 35 liquid system

No comments:

| Eco-Friendly Media Blasting |

Businesses often need solutions for surface preparation and cleaning. At the same time, they want these solutions to be compatible with environmental needs.

Monday, January 25, 2016

Welding Generators: Solution for Uninterrupted Power Supply

An ideal generator is one that

consumes little power, effectively uses fuel, and is cost-effective. The welding generators with precise power consumption will

result in the proper usage of fuel. They run on petrol, diesel, or LPG. The

diesel operating generators are durable and most fuel-efficient. However, the

repair and maintenance of such generators are expensive when compared to petrol

and LPG generators.

Welding

Generator Versus Simple Generator

A welding generator encompasses a longer run-time when compared to a simple generator. It is because of the huge fuel tank, making it function all through the day or night with refilling the tank. Its output lies between 4500 to 12000 units that are far better than that of the simple one. It offers efficient power capabilities at the same price. The high ambient temperature performance of the welding generator allows it to deliver the desired power even in harsh weather conditions.

A welding generator encompasses a longer run-time when compared to a simple generator. It is because of the huge fuel tank, making it function all through the day or night with refilling the tank. Its output lies between 4500 to 12000 units that are far better than that of the simple one. It offers efficient power capabilities at the same price. The high ambient temperature performance of the welding generator allows it to deliver the desired power even in harsh weather conditions.

The high peak power duration offers an

effective solution for most loads. It is useful in starting the motor of the

generator. The welding generators provide

a rigid voltage output that will not drop even with the excess load. However, a

voltage output of a simple generator will drop with heavy or medium loads.

Unlike the spiked power of the other, they offer smooth power. Therefore, they

are compatible in running electronic appliances that are sensitive to

fluctuations of the voltage.

Being

made with heavy-duty elements ensures the proper functionality and durability.

The best part is they have excellent resale value compared to simple

generators. They are durable, portable, and lightweight. They are easily

available at soldering supply distributors or retail stores at reasonable

prices.

Operating Precautions

Operating Precautions

- Do not operate the welding generator around explosives.

- Keep the generator away from sparks or open flames.

- Strictly prohibit smoking in the area around the generator

- Use the proper fuel and before filling fuel.

- Cool the engine.

To summarize, investing in welding generator is a sensible decision as it does not cost more compared to the simple generator and has excellent power generating capabilities.

Monday, January 18, 2016

Plasma Cutting Equipment - Offering a Solution for Metal Fabrication

Plasma cutters are the ideal equipment to cut any

electrically conductive material swiftly. The kind of system chosen depends on

factors like: thickness of the material and job requirements. Mechanized and

manual plasma cutting systems are

perfect for diverse applications but require different equipment. Apart from

handheld plasma cutters, there is a plethora of CNC plasma cutting equipment

ranging from heavy duty production to entry level job shops which are available

in the market.

What does Plasma Cutting

Mean?

Plasma cutting is a thermal cutting process where ionized

gas and heated metal that are electrically conductive above their melting point

and eradicate molten metal through the slit made in the cut. Plasma is a gas

that energizes and compresses to the stage where some of the electrons break

free from their nucleus and move freely. The pressurized gas ionizes at a very

high temperature between 140000 and 260000 F to produce

an electrical arc between the torch and the work piece.

After this, the plasma

constricts through a nozzle to produce an arc that cuts and melts various kinds

of metal. It is a standard process for both the mechanized and manual plasma

cutting systems including the XCS 2000 CNC Plasma cutters.

Benefits of Plasma

Cutters

Due to the high productivity and versatility, Plasma Cutters

offer excellent quality cut with few negative effects. When you contact the

prominent supplier, you will get all the machinery products with several

options and features to fulfill your needs. Such machines utilize high

frequency and are considered valuable means of cutting assorted range of

materials. Using these tools need

minimal heat input and warp with a clean edge. The major benefits of using such

machines are as follows:

- Improved edge quality

- Economical productivity

- Smoothness and cut appearance

- Little dross formation

- Cost savings

- Optimal cutting

- Quality improvements

- Design flexibility

- Ensure consistent performance

- Offers faster cutting over oxy fuel methods

If you are longing to buy a plasma cutter for your business or have any special requirements, then you can contact

a genuine seller at the nearest location. You can also place an online order

and get the product delivered to your doorsteps. The better the service

provider, the increased are its chances to ensure streamlined services and

on-time delivery of the machinery.